What are the Main Application Directions of Capacitor Capacity?

I. Introduction

Capacitors are fundamental components in electrical engineering, serving a variety of purposes across numerous applications. At the heart of their functionality lies the concept of capacitor capacity, or capacitance, which is the ability of a capacitor to store electrical energy. This blog post will explore the main application directions of capacitor capacity, highlighting its significance in energy storage, signal processing, power factor correction, filtering, motor control, telecommunications, and emerging technologies.

II. Fundamental Concepts of Capacitor Capacity

A. Explanation of Capacitance

Capacitance is defined as the ability of a capacitor to store charge per unit voltage. The unit of capacitance is the farad (F), which is a measure of how much electric charge a capacitor can hold at a given voltage. Several factors influence capacitance, including the surface area of the capacitor plates, the distance between them, and the type of dielectric material used.

B. Types of Capacitors

There are several types of capacitors, each with unique characteristics and applications:

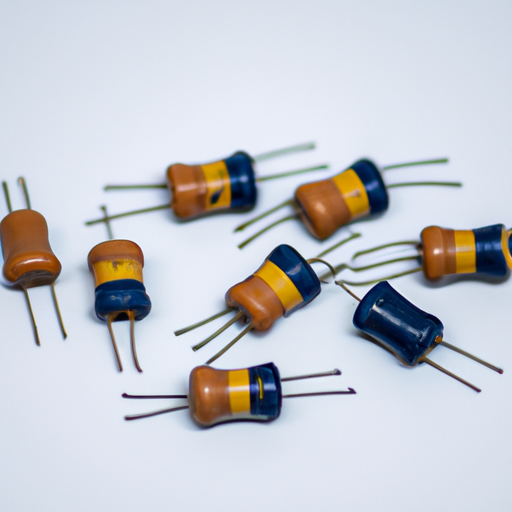

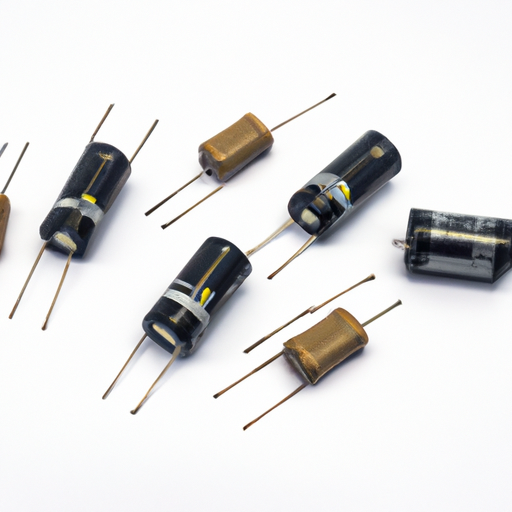

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and often used in power supply applications.

2. **Ceramic Capacitors**: These are non-polarized capacitors with a wide range of capacitance values, commonly used in high-frequency applications.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and low loss, making them suitable for audio and timing applications.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are often used in portable electronics.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles.

III. Energy Storage Applications

A. Power Supply Systems

Capacitors play a crucial role in power supply systems by smoothing and filtering voltage fluctuations. They store energy during periods of low demand and release it during peak demand, ensuring a stable power supply. In renewable energy systems, such as solar and wind, capacitors help manage the intermittent nature of energy generation, storing excess energy for later use.

B. Electric Vehicles

In electric vehicles (EVs), capacitors are integral to battery management systems, helping to regulate voltage and improve efficiency. They are also used in regenerative braking systems, where they capture and store energy generated during braking, allowing it to be reused to power the vehicle.

C. Consumer Electronics

Capacitors are ubiquitous in consumer electronics, providing power backup in mobile devices and energy storage in laptops and tablets. They ensure that devices operate smoothly, even during brief power interruptions.

IV. Signal Processing Applications

A. Coupling and Decoupling Capacitors

In audio and video equipment, coupling capacitors are used to connect different stages of a circuit while blocking DC voltage, allowing only AC signals to pass. Decoupling capacitors, on the other hand, filter out noise and stabilize voltage levels, ensuring signal integrity in communication systems.

B. Timing Circuits

Capacitors are essential in timing circuits, such as RC (resistor-capacitor) circuits, which determine the timing intervals in oscillators and timers. These circuits are widely used in clocks, timers, and various electronic devices.

V. Power Factor Correction

A. Definition and Importance of Power Factor

Power factor is a measure of how effectively electrical power is being converted into useful work output. A low power factor indicates poor efficiency, leading to higher energy costs and increased strain on electrical systems.

B. Role of Capacitors in Improving Power Factor

Capacitors are used in power factor correction to offset inductive loads, such as motors and transformers, which can cause a lagging power factor. By adding capacitors to the system, the overall power factor can be improved, resulting in reduced energy costs and enhanced system performance.

C. Applications in Industrial and Commercial Settings

Power factor correction is particularly important in industrial and commercial settings, where large machinery and equipment can lead to significant power factor penalties. Capacitors help mitigate these issues, improving energy efficiency and reducing operational costs.

VI. Filtering Applications

A. Low-Pass, High-Pass, Band-Pass, and Band-Stop Filters

Capacitors are key components in various types of filters, including low-pass, high-pass, band-pass, and band-stop filters. These filters are used to control the frequency response of electronic circuits, allowing certain frequencies to pass while attenuating others.

B. Use in Audio Equipment

In audio equipment, capacitors are used in crossover networks to direct specific frequency ranges to the appropriate speakers, ensuring optimal sound quality.

C. Applications in Radio Frequency (RF) Circuits

In RF circuits, capacitors are used to filter out unwanted signals and noise, ensuring clear communication and signal integrity.

VII. Capacitors in Motor Control

A. Starting Capacitors in Single-Phase Motors

Starting capacitors provide the necessary torque to start single-phase motors. They temporarily increase the motor's starting current, allowing it to overcome inertia and begin operation.

B. Run Capacitors for Efficiency Improvement

Run capacitors improve the efficiency of motors by providing a phase shift in the current, resulting in smoother operation and reduced energy consumption.

C. Applications in HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, capacitors are used to enhance the performance of motors, ensuring efficient operation and energy savings.

VIII. Capacitors in Telecommunications

A. Role in Signal Integrity

In telecommunications, capacitors are essential for maintaining signal integrity. They help filter out noise and stabilize voltage levels, ensuring clear and reliable communication.

B. Use in RF Amplifiers and Transmitters

Capacitors are used in RF amplifiers and transmitters to couple signals and filter unwanted frequencies, enhancing the performance of communication systems.

C. Applications in Data Transmission Systems

In data transmission systems, capacitors help manage signal integrity and timing, ensuring efficient and reliable data transfer.

IX. Emerging Applications and Future Directions

A. Advancements in Capacitor Technology

Recent advancements in capacitor technology have led to the development of higher capacity capacitors, which can store more energy in smaller packages. Flexible and printed capacitors are also emerging, opening new possibilities for integration into various devices.

B. Role in Smart Grids and IoT Devices

Capacitors are becoming increasingly important in smart grids and Internet of Things (IoT) devices, where they help manage energy storage and improve system efficiency.

C. Potential in Energy Harvesting Technologies

Capacitors hold potential in energy harvesting technologies, where they can store energy generated from ambient sources, such as solar or kinetic energy, for later use.

X. Conclusion

In summary, capacitor capacity plays a vital role in a wide range of applications, from energy storage and signal processing to power factor correction and telecommunications. As technology continues to advance, the importance of capacitors in modern systems will only grow, paving the way for innovative applications and improved efficiency. Understanding the various applications of capacitor capacity is essential for anyone involved in electrical engineering and related fields, as these components are integral to the functionality of countless devices and systems. The future of capacitor technology promises exciting developments that will further enhance their role in our increasingly connected and energy-efficient world.