Product

Product

NEW

NEW

-

What is led driver power conversion

-

How can high temperature polymer chip capacitors be used in automotive products?

-

What's the working principle of the LED driver boost/boost converter?

-

Chip multilayer ceramic capacitor, something many people don't know

-

How is tantalum capacitor closely related to the development of mobile phone industry

-

How Polymer Aluminum Capacitor can be used to maximize its effect

-

What causes the temperature of the film capacitor to be too high

-

Why more and more people choose to use polymer capacitors

-

Why must solid state capacitors be used for fast charging power supply

-

What important industry-related patents does the resistor box contain?

-

What are the top 10 popular standard resistor models?

-

What are the main applications of current sensing resistors?

-

What are the top 10 popular resistor connection methods?

-

What are the advantages of tool products?

-

What are the advantages of switch products?

-

An article to help you understand what is the role of resistors in circuits

-

What is the current situation of Shanghai's resistor industry?

-

What are the product standards for programmable resistors?

-

Definition specifications of the latest resistors

-

Main function specifications of the latest resistors

-

What are the product features of resistor wiring diagram?

-

What is the common production process of resistor rt54?

-

What are the product features of power wirewound resistors?

-

What are the product features of Crane Resistor Wiring Diagram?

-

What are the product features of resistor parameters?

-

Common resistor starter popular models

-

What are the product features of thermal resistors?

-

What is the role of resistor measurement products in practical applications?

-

What industries are the application scenarios of chip adjustable resistors included?

-

What is the role of strip resistor products in practical applications?

-

What kind of product is resistor L?

-

What are the common production processes for welding?

-

Mainstream tool product series parameters

-

Capacitor product training precautions

-

What are the latest desoldering manufacturing processes?

-

What is the production process of mainstream capacitors?

-

How to choose spot supercapacitors?

-

What are the mainstream models of capacitor formulas?

-

What product types are included in aluminum electrolytic capacitors?

-

What are the advantages of power capacitor products?

-

Mainstream film capacitor product series parameters

-

What is the price of popular electrolytic capacitor models in stock?

-

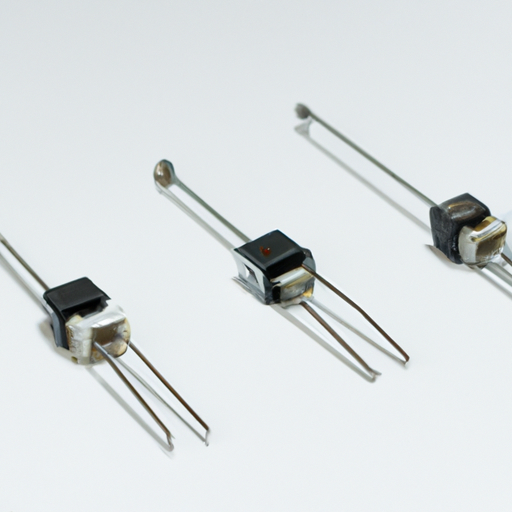

Popular models of common discrete semiconductor products

-

What is the role of coupling capacitor products in practical applications?

-

The latest capacitor bank specifications

-

What are the popular models of memory cards?

-

What are the important product categories of high-voltage capacitors?

-

What are the product standards for capacitors?

-

What product types do the capacitor symbols include?

-

What is the current situation of the fastener industry?

-

How big is the market for accessories?

-

What are the development trends in the capacitor principle industry?

-

What are the advantages of ceramic capacitor products?

-

Recommendations for similar pulse capacitor components

-

What kind of product are high-voltage shunt capacitors?

-

When will the new overload capacitor be released?

-

An article to help you understand what metallized film capacitors are

-

What is the price of popular supercapacitor structure models in stock?

-

Capacitors What are the product features of capacitors?

-

What is the role of capacitor products in practical applications?

-

What is the mainstream capacitor discharge production process?

-

Mainstream capacitor factory product series parameters

-

What are the development trends in the compensation capacitor industry?

-

What is the price of popular capacitor compensation models in stock?

-

An article to help you understand what is capacitor price

-

What are the product standards for capacitors and capacitors?

-

What are the main application directions of capacitors?

-

The latest capacitor is the capacitor specification sheet

-

What are the purchasing models of the latest capacitor current equipment components?

-

The latest capacitor function specifications

-

What are the product models of popular capacitors?

-

What are the main application directions of capacitor capacity?

-

What is the production process of mainstream air-conditioning capacitors?

-

What is the mainstream capacitor charging production process?

-

What is the price of popular low-voltage capacitor models in stock?

-

What are the product features of capacitor manufacturers?

-

What are the important product categories of parallel plate capacitors?

-

When will the new parallel plate capacitor capacitor be released

-

What industries are important patents related to capacitors and capacitors?

-

What kind of product is capacitor?

-

What are the prices of popular capacitors and capacitor models in stock?

-

What are the common production processes for capacitor films?

-

What are the product characteristics of capacitor pictures?

-

What is the latest capacitor? What are the procurement models of equipment components?

-

The latest capacitor company specifications

-

What product types are included in capacitor calculation?

-

An article will help you understand what smart capacitors are

-

What are the popular models of series capacitors?

-

What industries-related important patents do the capacitor capacitor formula contain?

-

What is the purchase price of the latest fan capacitor?

-

When will the new capacitor cabinet be released?

-

How big is the market size of capacitor resistors?

-

Mainstream capacitor model product series parameters

-

What types of products do capacitors cost?

-

What is the market size of capacitor protection?

-

What are the mainstream models of aluminum capacitors?

-

Mainstream capacitor brand product series parameters

-

What are the working principles of capacitors?

-

How should we choose to recycle spot capacitors?

-

What are the common production processes for capacitor grounding?

-

What are the product characteristics of capacitor parameters?

-

What are the popular models of Farara capacitors?

-

What are the popular models of the 10 mainstream capacitors c?

-

S6008L Resistors highlighting the core functional technology articles and application development cases of Resistors that are effective.

-

CFR-12JB-52-110R Resistors highlighting the core functional technology articles and application development cases of Resistors that are effective.

-

application development in Capacitors for ECS-F1CE225K: key technologies and success stories

-

ECS-F1HE475K Inductors, Coils, Chokes highlighting the core functional technology articles and application development cases of Inductors, Coils, Chokes that are effective.

-

application development in Potentiometers, Variable Resistors for ECS-F1HE335K: key technologies and success stories

-

ECS-F1HE155K Transformers highlighting the core functional technology articles and application development cases of Transformers that are effective.

-

application development in Discrete Semiconductor Products for CFR-50JB-52-1R: key technologies and success stories

-

MM74HC4050N Integrated Circuits (ICs) highlighting the core functional technology articles and application development cases of Integrated Circuits (ICs) that are effective.

-

application development in RF and Wireless for CFR-50JB-52-1K: key technologies and success stories

-

CFR-25JB-52-1K Resistor Networks, Arrays highlighting the core functional technology articles and application development cases of Resistor Networks, Arrays that are effective.

-

application development in Through Hole Resistors for MM74HC4049N: key technologies and success stories

-

CFR-50JB-52-1M Chassis Mount Resistors highlighting the core functional technology articles and application development cases of Chassis Mount Resistors that are effective.

-

application development in Specialized Resistors for CFR-25JB-52-1M: key technologies and success stories

-

CFR-25JB-52-1R Capacitor Networks, Arrays highlighting the core functional technology articles and application development cases of Capacitor Networks, Arrays that are effective.

-

application development in Aluminum Electrolytic Capacitors for MM74HC4040N: key technologies and success stories

-

CFR-50JB-52-1R1 Tantalum Capacitors highlighting the core functional technology articles and application development cases of Tantalum Capacitors that are effective.

-

application development in Ceramic Capacitors for MM74HC4020N: key technologies and success stories

-

How big is the market for audio equipment?

-

CFR-50JB-52-1K1 Electric Double Layer Capacitors (EDLC), Supercapacitors highlighting the core functional technology articles and application development cases of Electric Double Layer Capacitors (EDLC), Supercapacitors that are effective.

-

application development in Film Capacitors for CFR-25JB-52-1K1: key technologies and success stories

-

CFR-50JB-52-1M1 Mica and PTFE Capacitors highlighting the core functional technology articles and application development cases of Mica and PTFE Capacitors that are effective.

-

application development in Trimmers, Variable Capacitors for CFR-25JB-52-1M1: key technologies and success stories

-

CFR-25JB-52-1R1 Thin Film Capacitors highlighting the core functional technology articles and application development cases of Thin Film Capacitors that are effective.

-

application development in Niobium Oxide Capacitors for MM74HC393N: key technologies and success stories

-

CFR-50JB-52-1R2 Silicon Capacitors highlighting the core functional technology articles and application development cases of Silicon Capacitors that are effective.

-

application development in Aluminum - Polymer Capacitors for CFR-50JB-52-1K2: key technologies and success stories

-

CFR-25JB-52-1K2 Tantalum - Polymer Capacitors highlighting the core functional technology articles and application development cases of Tantalum - Polymer Capacitors that are effective.

-

application development in Fixed Inductors for MM74HC374N: key technologies and success stories

-

CFR-50JB-52-1M2 Adjustable Inductors highlighting the core functional technology articles and application development cases of Adjustable Inductors that are effective.

-

application development in Arrays, Signal Transformers for CFR-25JB-52-1M2: key technologies and success stories

-

CFR-25JB-52-1R2 Delay Lines highlighting the core functional technology articles and application development cases of Delay Lines that are effective.

-

application development in Wireless Charging Coils for MM74HC373N: key technologies and success stories

-

CFR-50JB-52-1R3 Accessories highlighting the core functional technology articles and application development cases of Accessories that are effective.

-

application development in Thumbwheel Potentiometers for CFR-50JB-52-1K3: key technologies and success stories

-

CFR-25JB-52-1K3 Slide Potentiometers highlighting the core functional technology articles and application development cases of Slide Potentiometers that are effective.

-

application development in Trimmer Potentiometers for CFR-50JB-52-1M3: key technologies and success stories

-

CFR-25JB-52-1M3 Value Display Potentiometers highlighting the core functional technology articles and application development cases of Value Display Potentiometers that are effective.

-

application development in Joystick Potentiometers for CFR-25JB-52-1R3: key technologies and success stories

-

LT1213CS8 Adjustable Power Resistor highlighting the core functional technology articles and application development cases of Adjustable Power Resistor that are effective.

-

application development in Rotary Potentiometers, Rheostats for CFR-50JB-52-1R5: key technologies and success stories

-

CFR-50JB-52-1K5 Accessories highlighting the core functional technology articles and application development cases of Accessories that are effective.

-

application development in Audio Transformers for CFR-25JB-52-1K5: key technologies and success stories

-

CFR-50JB-52-1M5 Current Sense Transformers highlighting the core functional technology articles and application development cases of Current Sense Transformers that are effective.

-

application development in Power Transformers for CFR-25JB-52-1M5: key technologies and success stories

-

CFR-25JB-52-1R5 Specialty Transformers highlighting the core functional technology articles and application development cases of Specialty Transformers that are effective.

-

application development in Pulse Transformers for CFR-50JB-52-1R6: key technologies and success stories

-

CFR-50JB-52-1K6 Isolation Transformers and Autotransformers, Step Up, Step Down highlighting the core functional technology articles and application development cases of Isolation Transformers and Autotransformers, Step Up, Step Down that are effective.

-

application development in Switching Converter, SMPS Transformers for CFR-25JB-52-1K6: key technologies and success stories

-

CFR-50JB-52-1M6 DIACs, SIDACs highlighting the core functional technology articles and application development cases of DIACs, SIDACs that are effective.

-

application development in Single FETs, MOSFETs for CFR-50JB-52-1R8: key technologies and success stories

-

MM74HC259N Single IGBTs highlighting the core functional technology articles and application development cases of Single IGBTs that are effective.

-

application development in Single Diodes for CFR-50JB-52-1K8: key technologies and success stories

-

CFR-25JB-52-1K8 SCRs highlighting the core functional technology articles and application development cases of SCRs that are effective.

-

application development in Variable Capacitance (Varicaps, Varactors) for CFR-50JB-52-1M8: key technologies and success stories

-

application development in RF Diodes for CFR-25JB-52-1R8: key technologies and success stories

-

MM74HC251N RF FETs, MOSFETs highlighting the core functional technology articles and application development cases of RF FETs, MOSFETs that are effective.

-

application development in Diode Arrays for CFR-50JB-52-100R: key technologies and success stories

-

MM74HC245AN Single Zener Diodes highlighting the core functional technology articles and application development cases of Single Zener Diodes that are effective.

-

application development in JFETs for CFR-50JB-52-100K: key technologies and success stories

-

CFR-25JB-52-100K FET, MOSFET Arrays highlighting the core functional technology articles and application development cases of FET, MOSFET Arrays that are effective.

-

application development in Programmable Unijunction for CFR-25JB-52-100R: key technologies and success stories

-

2474-26L IGBT Arrays highlighting the core functional technology articles and application development cases of IGBT Arrays that are effective.

-

application development in Special Purpose for CFR-50JB-52-10R: key technologies and success stories

-

MM74HC244N Zener Diode Arrays highlighting the core functional technology articles and application development cases of Zener Diode Arrays that are effective.

-

application development in Power Driver Modules for CFR-50JB-52-10K: key technologies and success stories

-

CFR-25JB-52-10K IGBT Modules highlighting the core functional technology articles and application development cases of IGBT Modules that are effective.

-

application development in SCRs - Modules for CFR-25JB-52-10R: key technologies and success stories

-

LT1178ACN8 Bridge Rectifiers highlighting the core functional technology articles and application development cases of Bridge Rectifiers that are effective.

-

application development in Single Bipolar Transistors for CFR-25JB-52-1M6: key technologies and success stories

-

CFR-25JB-52-1R6 Bipolar Transistor Arrays highlighting the core functional technology articles and application development cases of Bipolar Transistor Arrays that are effective.

-

CFR-25JB-52-1M8 Bipolar RF Transistors highlighting the core functional technology articles and application development cases of Bipolar RF Transistors that are effective.

-

application development in Single, Pre-Biased Bipolar Transistors for ECQ-P1H333GZ: key technologies and success stories

-

ECQ-P1H153GZ Bipolar Transistor Arrays, Pre-Biased highlighting the core functional technology articles and application development cases of Bipolar Transistor Arrays, Pre-Biased that are effective.

-

application development in TRIACs for ECS-F1VE685K: key technologies and success stories

-

CFR-50JB-52-110R Sensor, Capacitive Touch highlighting the core functional technology articles and application development cases of Sensor, Capacitive Touch that are effective.

-

application development in Laser Drivers for MM74HC241N: key technologies and success stories

-

CFR-50JB-52-110K Signal Terminators highlighting the core functional technology articles and application development cases of Signal Terminators that are effective.

-

application development in Video Processing for CFR-25JB-52-110K: key technologies and success stories

-

CFR-25JB-52-110R Microcontrollers highlighting the core functional technology articles and application development cases of Microcontrollers that are effective.

-

application development in Specialized ICs for IRF510: key technologies and success stories

-

ECS-F1VE155K Instrumentation, OP Amps, Buffer Amps highlighting the core functional technology articles and application development cases of Instrumentation, OP Amps, Buffer Amps that are effective.

-

application development in Delay Lines for CFR-50JB-52-11R: key technologies and success stories

-

MM74HC240N Programmable Timers and Oscillators highlighting the core functional technology articles and application development cases of Programmable Timers and Oscillators that are effective.

-

application development in Real Time Clocks for CFR-50JB-52-11K: key technologies and success stories

-

CFR-25JB-52-11K Supervisors highlighting the core functional technology articles and application development cases of Supervisors that are effective.

-

application development in Comparators for CFR-25JB-52-11R: key technologies and success stories

-

MM74HC221AN Voltage Reference highlighting the core functional technology articles and application development cases of Voltage Reference that are effective.

-

application development in Microprocessors for CFR-50JB-52-120R: key technologies and success stories

-

CFR-50JB-52-120K CPLDs (Complex Programmable Logic Devices) highlighting the core functional technology articles and application development cases of CPLDs (Complex Programmable Logic Devices) that are effective.

-

application development in FPGAs (Field Programmable Gate Array) for CFR-25JB-52-120K: key technologies and success stories

-

CFR-25JB-52-120R Configuration PROMs for FPGAs highlighting the core functional technology articles and application development cases of Configuration PROMs for FPGAs that are effective.

-

application development in DSP (Digital Signal Processors) for 2474-14L: key technologies and success stories

-

9250-686 Voltage Regulators - Linear, Low Drop Out (LDO) Regulators highlighting the core functional technology articles and application development cases of Voltage Regulators - Linear, Low Drop Out (LDO) Regulators that are effective.

-

application development in Analog to Digital Converters (ADC) for CFR-50JB-52-12R: key technologies and success stories

-

CFR-50JB-52-12K Digital to Analog Converters (DAC) highlighting the core functional technology articles and application development cases of Digital to Analog Converters (DAC) that are effective.

-

application development in Telecom for CFR-25JB-52-12K: key technologies and success stories

-

CFR-25JB-52-12R Specialty Logic highlighting the core functional technology articles and application development cases of Specialty Logic that are effective.

-

application development in Buffers, Drivers, Receivers, Transceivers for MM74HC175N: key technologies and success stories

-

MM74HC174N Gates and Inverters highlighting the core functional technology articles and application development cases of Gates and Inverters that are effective.

-

application development in Flip Flops for CFR-50JB-52-130R: key technologies and success stories

-

MM74HC165N FIFOs Memory highlighting the core functional technology articles and application development cases of FIFOs Memory that are effective.

-

application development in Latches for CFR-50JB-52-130K: key technologies and success stories

-

CFR-25JB-52-130K Encoders, Decoders, Converters highlighting the core functional technology articles and application development cases of Encoders, Decoders, Converters that are effective.

-

application development in Drivers, Receivers, Transceivers for CFR-25JB-52-130R: key technologies and success stories

-

ECS-F1EE336 Multivibrators highlighting the core functional technology articles and application development cases of Multivibrators that are effective.

-

application development in Shift Registers for CFR-50JB-52-13R: key technologies and success stories

-

MM74HC164N Battery Management highlighting the core functional technology articles and application development cases of Battery Management that are effective.

-

application development in UARTs (Universal Asynchronous Receiver Transmitter) for CFR-50JB-52-13K: key technologies and success stories

-

CFR-25JB-52-13K DC DC Switching Controllers highlighting the core functional technology articles and application development cases of DC DC Switching Controllers that are effective.

-

application development in CODECS for CFR-25JB-52-13R: key technologies and success stories

-

2N5064 Digital Potentiometers highlighting the core functional technology articles and application development cases of Digital Potentiometers that are effective.

-

application development in Hot Swap Controllers for MM74HC163N: key technologies and success stories

-

CFR-50JB-52-150R PLDs (Programmable Logic Device) highlighting the core functional technology articles and application development cases of PLDs (Programmable Logic Device) that are effective.

-

application development in Parity Generators and Checkers for MM74HC161N: key technologies and success stories

-

CFR-50JB-52-150K Microcontrollers, Microprocessor, FPGA Modules highlighting the core functional technology articles and application development cases of Microcontrollers, Microprocessor, FPGA Modules that are effective.

-

application development in Modems - ICs and Modules for CFR-25JB-52-150K: key technologies and success stories

-

CFR-25JB-52-150R Direct Digital Synthesis (DDS) highlighting the core functional technology articles and application development cases of Direct Digital Synthesis (DDS) that are effective.

-

application development in Analog Front End (AFE) for CFR-50JB-52-15R: key technologies and success stories

-

CFR-50JB-52-15K Universal Bus Functions highlighting the core functional technology articles and application development cases of Universal Bus Functions that are effective.

-

CFR-25JB-52-15K V/F and F/V Converters highlighting the core functional technology articles and application development cases of V/F and F/V Converters that are effective.

-

application development in Clock Generators, PLLs, Frequency Synthesizers for CFR-25JB-52-15R: key technologies and success stories

-

MM74HC157N Display Drivers highlighting the core functional technology articles and application development cases of Display Drivers that are effective.

-

application development in Gate Drivers for CFR-50JB-52-160R: key technologies and success stories

-

MM74HC154N Counters, Dividers highlighting the core functional technology articles and application development cases of Counters, Dividers that are effective.

-

application development in Translators, Level Shifters for CFR-50JB-52-160K: key technologies and success stories

-

CFR-25JB-52-160K Voice Record and Playback highlighting the core functional technology articles and application development cases of Voice Record and Playback that are effective.

-

application development in Current Regulation/Management for CFR-25JB-52-160R: key technologies and success stories

-

CFR-50JB-52-16R Filters - Active highlighting the core functional technology articles and application development cases of Filters - Active that are effective.

-

application development in Controllers for CFR-50JB-52-16K: key technologies and success stories

-

CFR-25JB-52-16K Video Amps and Modules highlighting the core functional technology articles and application development cases of Video Amps and Modules that are effective.

-

application development in Thermal Management for CFR-25JB-52-16R: key technologies and success stories

-

EXB-V4V120JV Voltage Regulators - DC DC Switching Regulators highlighting the core functional technology articles and application development cases of Voltage Regulators - DC DC Switching Regulators that are effective.

-

application development in RMS to DC Converters for ECS-F1EE106K: key technologies and success stories

-

MM74HC151N Audio Special Purpose highlighting the core functional technology articles and application development cases of Audio Special Purpose that are effective.

-

application development in Audio Amplifiers for CFR-50JB-52-180R: key technologies and success stories

-

MM74HC139N Signal Switches, Multiplexers, Decoders highlighting the core functional technology articles and application development cases of Signal Switches, Multiplexers, Decoders that are effective.

-

application development in Motor Drivers, Controllers for CFR-50JB-52-180K: key technologies and success stories

-

CFR-25JB-52-180K LED Drivers highlighting the core functional technology articles and application development cases of LED Drivers that are effective.

-

application development in Full Half-Bridge (H Bridge) Drivers for CFR-25JB-52-180R: key technologies and success stories

-

ECS-F1EE475K Analog Switches, Multiplexers, Demultiplexers highlighting the core functional technology articles and application development cases of Analog Switches, Multiplexers, Demultiplexers that are effective.

-

application development in AC DC Converters, Offline Switches for CFR-50JB-52-18R: key technologies and success stories

-

MM74HC138N I/O Expanders highlighting the core functional technology articles and application development cases of I/O Expanders that are effective.

-

application development in Special Purpose Regulators for CFR-50JB-52-18K: key technologies and success stories

-

CFR-25JB-52-18K Lighting, Ballast Controllers highlighting the core functional technology articles and application development cases of Lighting, Ballast Controllers that are effective.

-

application development in Sensor and Detector Interfaces for CFR-25JB-52-18R: key technologies and success stories

-

1N4001-T Controllers highlighting the core functional technology articles and application development cases of Controllers that are effective.

-

application development in Specialized for 1N4002-T: key technologies and success stories

-

1N4003-T Serializers, Deserializers highlighting the core functional technology articles and application development cases of Serializers, Deserializers that are effective.

-

application development in Signal Buffers, Repeaters, Splitters for 1N4004-T: key technologies and success stories

-

1N4005-T Voltage Regulators - Linear Regulator Controllers highlighting the core functional technology articles and application development cases of Voltage Regulators - Linear Regulator Controllers that are effective.

-

application development in OR Controllers, Ideal Diodes for 1N4006-T: key technologies and success stories

-

1N4007-T PFC (Power Factor Correction) highlighting the core functional technology articles and application development cases of PFC (Power Factor Correction) that are effective.

-

application development in Power Supply Controllers, Monitors for 1N4148-T: key technologies and success stories

-

1N5228B-T Power Management - Specialized highlighting the core functional technology articles and application development cases of Power Management - Specialized that are effective.

-

application development in IC Batteries for 1N5230B-T: key technologies and success stories

-

1N5231B-T Application Specific Clock/Timing highlighting the core functional technology articles and application development cases of Application Specific Clock/Timing that are effective.

-

application development in Clock Buffers, Drivers for 1N5232B-T: key technologies and success stories

-

1N5233B-T Energy Metering highlighting the core functional technology articles and application development cases of Energy Metering that are effective.

-

application development in Batteries for 1N5234B-T: key technologies and success stories

-

1N5235B-T FPGAs (Field Programmable Gate Array) with Microcontrollers highlighting the core functional technology articles and application development cases of FPGAs (Field Programmable Gate Array) with Microcontrollers that are effective.

-

application development in ADCs/DACs - Special Purpose for 1N5236B-T: key technologies and success stories

-

1N5237B-T Application Specific Microcontrollers highlighting the core functional technology articles and application development cases of Application Specific Microcontrollers that are effective.

-

application development in Gates and Inverters - Multi-Function, Configurable for 1N5238B-T: key technologies and success stories

-

1N5239B-T Special Purpose Amplifiers highlighting the core functional technology articles and application development cases of Special Purpose Amplifiers that are effective.

-

application development in Analog Multipliers, Dividers for 1N5240B-T: key technologies and success stories

-

1N5241B-T Comparators highlighting the core functional technology articles and application development cases of Comparators that are effective.

-

application development in Memory for 1N5242B-T: key technologies and success stories

-

1N5243B-T Touch Screen Controllers highlighting the core functional technology articles and application development cases of Touch Screen Controllers that are effective.

-

application development in Voltage Regulators - Linear + Switching for 1N5244B-T: key technologies and success stories

-

1N5245B-T System On Chip (SoC) highlighting the core functional technology articles and application development cases of System On Chip (SoC) that are effective.

-

application development in Modules for S6008L: key technologies and success stories

-

CFR-12JB-52-110R Power Over Ethernet (PoE) Controllers highlighting the core functional technology articles and application development cases of Power Over Ethernet (PoE) Controllers that are effective.

-

application development in Analog Switches - Special Purpose for S6008L: key technologies and success stories

-

CFR-12JB-52-110R Battery Chargers highlighting the core functional technology articles and application development cases of Battery Chargers that are effective.

-

application development in Balun for ECS-F1CE225K: key technologies and success stories

-

ECS-F1HE475K RF Directional Coupler highlighting the core functional technology articles and application development cases of RF Directional Coupler that are effective.

Contact us